Long History of Bankability

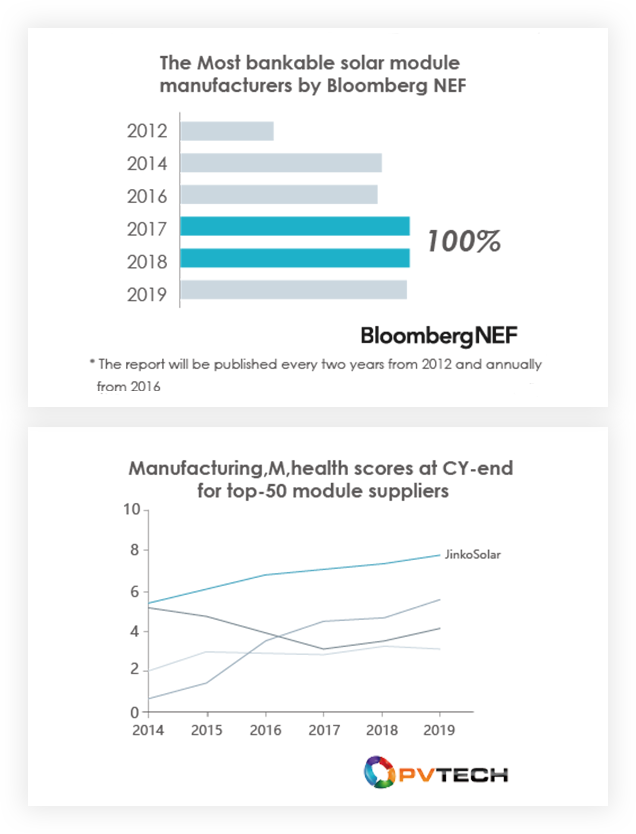

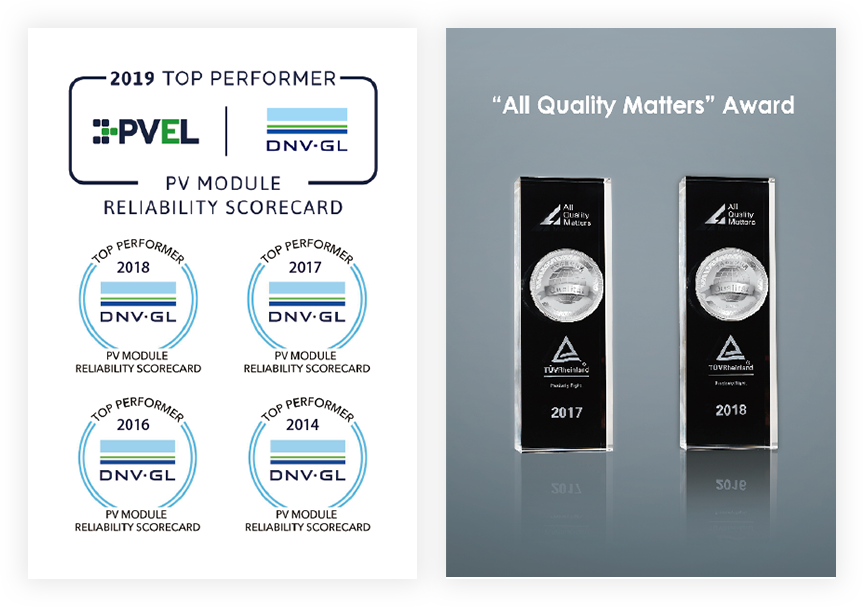

JinkoSolar has been named a Bloomberg NEF Tier 1 module manufacturer for eight consecutive years, which is one of the longest runs of any manufacturer.

In addition, JinkoSolar has received a top rating in the PV ModuleTech Bankability Ratings list published by PV TECH in August 2019. Only four companies were rated as AA (none AAA), and JinkoSolar is the only PV module supplier to have maintained a AA rating for the past 12 consecutive quarters.

PV TECH’s new PV ModuleTech Bankability Rating is an industry analysis that combines each company’s track-record in large-scale global shipments, with its financial health, on a rolling quarterly basis. The analysis uses data collected over 10 years at PV-Tech, across a wealth of manufacturing and financial inputs. Both the BNEF and PV Tech reports confirm why JinkoSolar has been so effective in gaining market-share globally, especially in utility-scale solar markets with rigorous standards.

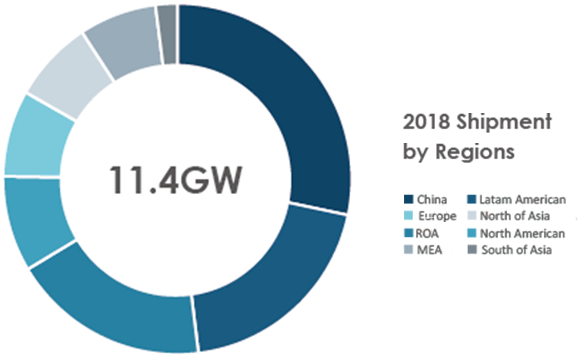

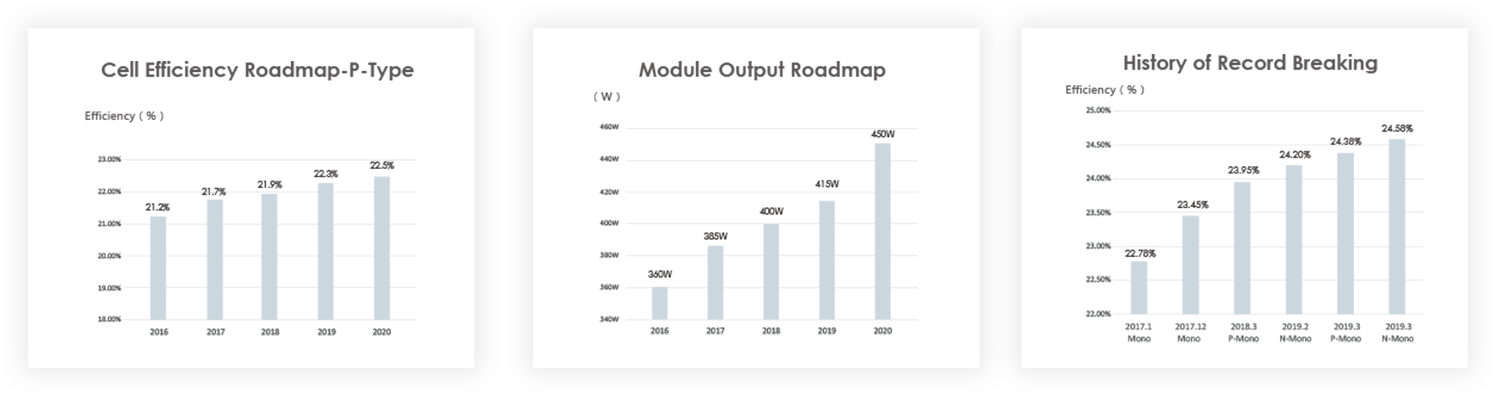

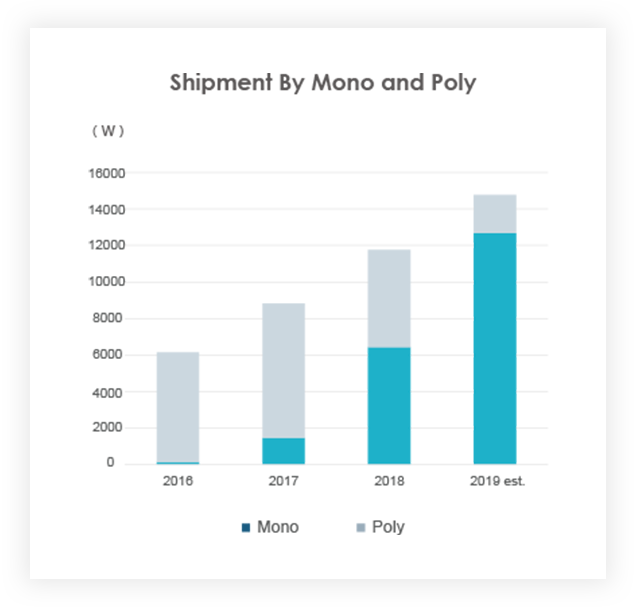

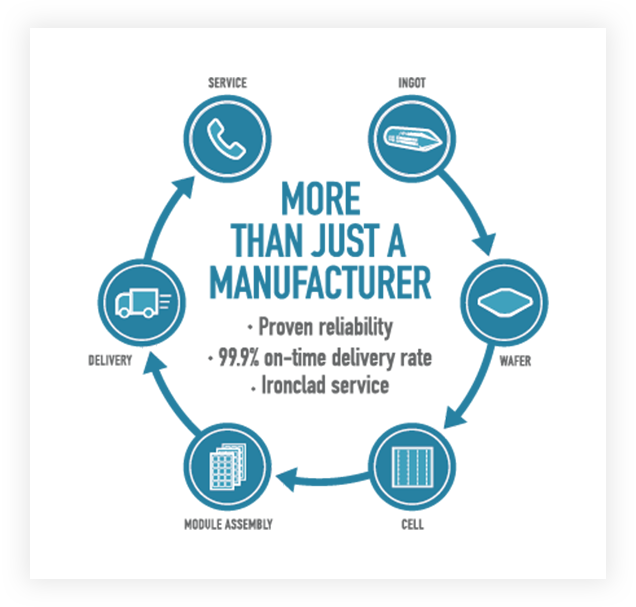

JinkoSolar’s growth has been a result of a carefully considered ramp of in-house wafer, cell, and module capacities, with frequent investments in R&D and capacity expansion. Large capacities in China and quick decisions to expand significantly in Southeast Asia and the U.S. has also been key to maximizing the strength and flexibility of JinkoSolar’s manufacturing capability.